Falling Weight Deflectometer (FWD)

Falling Weight Deflectometer (FWD) Test

Pavement management is a critical aspect of road infrastructure development and maintenance, as it ensures that roads can withstand the stresses induced by traffic, weather conditions, and time. Pavement evaluation methods have evolved over the years to provide engineers with the tools necessary to assess the strength, durability, and structural integrity of pavements in a non-destructive and efficient manner. One such technique is the Falling Weight Deflectometer (FWD) test, a widely accepted method for assessing the structural condition of both flexible and rigid pavements.

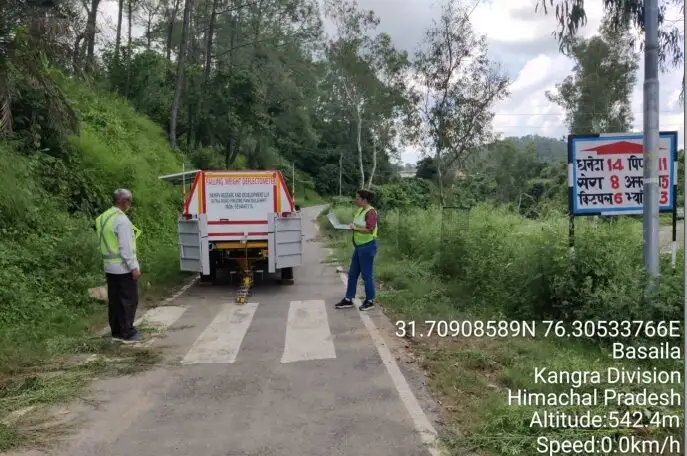

The Falling Weight Deflectometer (FWD) is a mobile device used to evaluate the pavement’s response to a load that simulates the impact of a moving vehicle. The test measures the deflection of the pavement surface when a weight is dropped from a predetermined height onto the surface of the road. This deflection provides key insights into the underlying layers of the pavement structure, including the surface, base, and subgrade materials. FWD testing is critical for engineers and pavement management systems, helping them understand the pavement’s ability to carry traffic loads and identifying areas that may require rehabilitation or maintenance.

This test mimics real-world traffic conditions by replicating the load exerted by a moving vehicle, typically using a controlled, falling weight that impacts the pavement through a loading plate. The data collected from the deflection measurements is used to assess the overall structural capacity of the pavement, determine whether the subgrade is adequately supporting the pavement, and evaluate the need for repairs or upgrades. The FWD test also assists in the back-calculation of material properties for pavement design, providing engineers with essential data to predict the remaining service life of a pavement structure.

The FWD test is unique in its ability to provide valuable information about the condition of both the surface and underlying layers of the pavement. The deflection profile generated during the test can be used to evaluate the strength and stiffness of the pavement’s individual layers, such as the surface course, base course, and subbase, as well as the modulus of elasticity of the underlying subgrade. This allows for the identification of weak spots or distress in the pavement that could lead to failures like cracking, rutting, or potholes.

In the context of India, the National Highways Authority of India (NHAI) has adopted FWD testing as part of its guidelines for pavement evaluation. The NHAI has set specific standards for the number of tests, test locations, frequency, and interpretation of results to ensure the longevity and safety of the national highways. This adherence to standards ensures that the FWD test not only assesses the present condition of pavements but also helps inform future maintenance and rehabilitation strategies, preventing premature deterioration and optimizing pavement management.

The growing demands for road infrastructure, combined with increasing traffic loads and environmental stress, make the FWD test indispensable for pavement management, as it enables early detection of structural problems and facilitates cost-effective decision-making for repairs and rehabilitation. As a non-destructive, reliable, and efficient method, the FWD test has become an essential tool for evaluating the long-term performance and safety of pavements on highways, urban roads, and other transportation networks.

This report delves deeper into the FWD test’s equipment, procedure, analysis of deflection data, and its alignment with the NHAI guidelines. Understanding the significance of this test in pavement management and maintenance is crucial for ensuring the sustainability and safety of road infrastructure in India and beyond.

By analyzing the deflection responses generated through FWD testing, engineers can make data-driven decisions about pavement rehabilitation, design improvements, and load-carrying capacity to ensure a more durable and cost-effective road network. In this context, the FWD test is not just a tool for measuring pavement conditions, but a vital part of ensuring the long-term resilience of road networks in the face of increasing traffic volumes and changing environmental conditions.

FWD Test Equipment and Components

The Falling Weight Deflectometer consists of several essential components designed to simulate the impact of traffic loads and measure the pavement’s deflection response. These include:

- Falling Weight: Typically weighing between 4.5 and 15 tons, the falling weight is calibrated to replicate the load exerted by moving vehicles, especially heavy trucks.

- Release Mechanism: A hydraulic or mechanical device controls the release of the weight. It is designed to ensure that the weight falls consistently, simulating real traffic-induced forces.

- Loading Plate: A circular steel plate (commonly 300 mm or 450 mm in diameter) is used to distribute the falling weight over the pavement surface. The plate’s uniform shape ensures that the force is applied consistently to the pavement.

- Deflection Sensors (Geophones): Multiple deflection sensors are placed radially around the loading plate to measure the pavement’s deflection at different distances from the point of impact. These sensors are highly sensitive and capable of recording minute deflections.

- Control Unit: The control unit governs the operation of the FWD test by initiating the release of the weight and recording the deflection data from the sensors. Modern FWD systems also provide real-time data display and analysis.

Test Procedure

The FWD test is conducted in the following steps, as per industry standards and NHAI guidelines:

- Site Selection and Preparation: The location for testing is chosen based on the project requirements. The area must be cleared of debris, and the pavement surface should be clean and dry. The test is generally conducted at regular intervals along the test section to obtain comprehensive data.

- Calibration of the Equipment: Before testing, the FWD system is calibrated according to the manufacturer’s instructions to ensure accurate measurements. Calibration involves adjusting the release mechanism and confirming the weight’s dropping height and velocity.

- Positioning the Equipment: The FWD equipment is positioned at predetermined locations along the pavement surface. The position of the equipment should ensure that the load is applied uniformly to the pavement. Multiple test points are chosen to account for variations in pavement conditions.

- Data Acquisition: The equipment operator releases the weight, causing it to fall onto the loading plate. The deflection at different radial distances is recorded by the geophones. The deflection measurements are taken at various load levels and are repeated at several locations along the pavement.

- Test Repetition: A minimum of three drops is usually required at each test location to ensure consistency and reliability of the data. Each drop will produce a unique deflection profile.

Deflection Data and Analysis

The data collected during the FWD test includes the deflection at various points around the load application. This deflection data is crucial in assessing the pavement structure’s performance and can be used to derive several important parameters, including:

- Deflection Basin or Bowl: This refers to the graphical representation of deflection values at different radial distances from the loading point. The deflection is highest at the center and decreases as the distance from the load increases. The shape of the deflection basin provides insights into the structural condition of the pavement.

- Subgrade Modulus (k-value): The k-value is a measure of the stiffness of the underlying subgrade material. This value is essential for understanding the overall support the subgrade provides to the pavement. Higher deflections may indicate weaker subgrades.

- Layer Moduli: By performing a back-calculation using deflection data, the moduli of individual pavement layers (surface, base, and subbase) can be determined. These moduli are crucial for evaluating the material strength and structural capacity of the pavement layers.

- Pavement Performance Evaluation: Based on the deflection profiles, engineers can evaluate whether the pavement is exhibiting early signs of distress, such as cracking, rutting, or other structural failures. The data also helps predict the remaining life of the pavement under current traffic loads.

- Structural Number (SN): The Structural Number is derived from the deflection data and is used to quantify the overall strength of the pavement structure. The SN is a key parameter used in pavement design and rehabilitation decisions.

NHAI Guidelines and Standards for FWD Testing

The National Highways Authority of India (NHAI) provides specific guidelines for the use of FWD testing in highway projects. These guidelines ensure consistency, accuracy, and reliability of the data collected. Some important NHAI guidelines and industry codes for FWD testing include:

- Test Locations: NHAI requires that FWD testing be carried out at regular intervals along the test section. The frequency and location of testing depend on the project requirements and the extent of the pavement.

- Number of Drops: A minimum of three drops must be performed at each test location. This ensures that any variability in deflection measurements is accounted for and that the data is reliable.

- Distance Between Sensors: NHAI guidelines specify the placement of deflection sensors at various distances from the loading point. Common distances are 0, 150, 300, 450, and 600 mm, with additional sensors placed at greater distances for highly flexible pavements.

- Calibration Requirements: FWD equipment must be calibrated periodically to ensure that it provides accurate and reliable results. Calibration standards, including the equipment’s release mechanism and sensor calibration, must be followed as per NHAI specifications.

- Data Reporting: The deflection data must be compiled and presented in a clear and detailed report. This report includes the deflection basin, pavement condition analysis, and any recommendations for maintenance or rehabilitation.

- Quality Control: NHAI mandates that FWD testing be conducted by qualified personnel who have undergone proper training in the operation of FWD equipment and the interpretation of deflection data.

Applications of FWD Testing

FWD testing is widely applied in various stages of pavement management and highway infrastructure projects. Its primary applications include:

- Pavement Condition Assessment: FWD testing is used to assess the structural integrity of existing pavements. By measuring the deflection response, engineers can evaluate whether a pavement is capable of supporting the current and future traffic loads.

- Pavement Rehabilitation and Maintenance: FWD results are crucial in determining whether a pavement requires rehabilitation, strengthening, or resurfacing. If the deflection exceeds permissible limits, remedial measures such as milling, overlaying, or base strengthening may be required.

- Pavement Design and Structural Evaluation: In new pavement construction, FWD testing helps assess the structural capacity of the designed pavement and validate its ability to carry the expected traffic loads. Engineers can use FWD data to back-calculate layer moduli and refine the pavement design.

- Traffic Load Analysis: FWD testing helps evaluate whether the pavement can carry the load exerted by vehicular traffic, particularly in areas with high heavy truck traffic. The test results assist in designing pavements that can withstand future traffic loads.

- Post-Construction Monitoring: After a new pavement is constructed, FWD testing can be used for post-construction performance monitoring. The data helps determine whether the pavement has been constructed as per the design specifications and if it is performing optimally.

Advantages of FWD Testing

- Non-Destructive: FWD testing is a non-destructive evaluation method, meaning it does not damage or disturb the pavement being tested.

- Rapid Data Collection: Multiple measurements can be obtained quickly, making it possible to test large sections of pavement in a short time frame.

- In-Situ Testing: The FWD test provides real-world data directly from the pavement, making it highly relevant to actual pavement performance under traffic loads.

- Comprehensive Results: The data collected from the FWD test gives a detailed assessment of both the surface and sub-surface conditions of the pavement structure.

- Cost-Effective: Although the initial cost of the equipment may be high, the FWD test is cost-effective compared to other traditional testing methods, especially for large-scale projects.

Limitations of FWD Testing

- Limited Depth Information: FWD testing primarily measures the deflection at the surface and provides indirect information about deeper pavement layers. The test cannot directly measure conditions at greater depths without additional analysis techniques.

- Weather Sensitivity: Extreme weather conditions such as rain or snow can affect the accuracy of the measurements.

- Equipment Cost: FWD devices are expensive to procure and maintain, which can be a limitation for smaller projects.

- Data Interpretation: Proper interpretation of deflection data requires skilled personnel and can be complex, particularly in situations where back-calculation of moduli is required.

Conclusion

Falling Weight Deflectometer (FWD) test is an essential tool for evaluating the structural performance of pavements in highway and infrastructure projects. It provides valuable insights into the condition of pavement surfaces and substructures, allowing engineers to make informed decisions about maintenance, rehabilitation, and design. Adherence to NHAI guidelines and industry standards ensures that FWD testing provides reliable and accurate data, which is crucial for maintaining the safety, longevity, and performance of road networks.

FWD testing, with its non-destructive nature and rapid data acquisition capabilities, plays a key role in pavement management systems. As infrastructure demands increase, the application of FWD testing in regular pavement evaluations becomes increasingly important for the sustainability of road networks.