Core cutting of asphalt pavements and concrete

Core cutting of asphalt pavements and concrete

- Introduction

Core cutting is a vital technique in civil engineering used to assess the quality, durability, and overall structural integrity of asphalt pavements and concrete structures. By extracting cylindrical samples of pavement or concrete from an in-situ structure, engineers can perform detailed tests that offer insight into the material’s performance under real-world conditions. These tests play a pivotal role in ensuring that materials meet specific quality standards, adhere to design requirements, and are capable of withstanding traffic loads, weather conditions, and other environmental stressors over time.

Core cutting is one of the most effective non-destructive methods available for evaluating the performance of both asphalt and concrete pavements. The data obtained from core cutting tests help guide construction quality control, maintenance planning, and future design improvements.

- Testing of Core Cutting in Asphalt Pavements

2.1 Description of Core Cutting in Asphalt Pavements

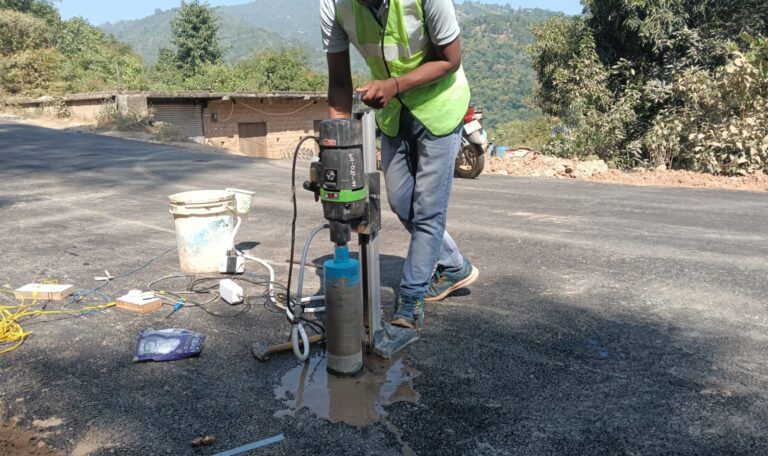

Core cutting for asphalt pavements involves extracting cylindrical samples from the pavement using a specialized core drill. The process is conducted on the finished pavement after it has cured to assess its quality, material composition, and the structural integrity of the asphalt layers. Core cutting helps determine critical properties, such as the binder content, air voids, aggregate gradation, and density of the asphalt mixture.

This technique provides an accurate and direct assessment of how the pavement was constructed and whether it meets the required standards. Additionally, it helps identify construction defects such as insufficient compaction, improper layer thickness, or non-compliance with the binder content specifications.

2.2 Core Cutting Procedure for Asphalt Pavements

The core cutting procedure typically includes the following steps:

- Preparation: The pavement surface is cleaned of any debris, oil, or loose materials before drilling to prevent contamination of the sample. The drilling location is selected to represent different areas of the pavement, ensuring that the core samples are representative of the entire structure.

- Drilling: A core drilling machine is used to extract samples, often with a diamond-tipped drill bit. The drill bit is typically between 100 mm to 150 mm in diameter. The core is extracted with minimal disturbance to the surrounding material.

- Handling and Transport: After extraction, the core is immediately labeled with vital information such as the location, depth, and date of extraction. The core is then transported to the laboratory under controlled conditions to avoid damage and ensure accurate test results.

2.3 Core Cutting Tests and Parameters in Asphalt

Several critical parameters are tested on the extracted core samples to assess the asphalt mix:

- Binder Content: The binder content is measured by dissolving the bitumen in a solvent and comparing the mass of the binder to the total mass of the core. The appropriate binder content ensures the pavement’s durability and flexibility.

- Air Voids: The air void content of the sample indicates the level of compaction. A lower air void content generally indicates better compaction and resistance to deformation.

- Aggregate Gradation: The aggregate mix’s particle size distribution is tested to verify whether it matches the required specifications. Well-graded aggregates enhance the pavement’s stability and durability.

- Density: The density of the extracted core is measured, and its compactness is compared to the standard values specified in the design. Proper density indicates that the pavement will resist deformation from traffic loads.

2.4 Importance of Core Cutting in Asphalt Pavement Testing

Core cutting provides several advantages, especially in the context of quality control and verification:

- Verification of Material Quality: Ensures that the asphalt mix used is of high quality and meets the specified standards for binder content, aggregate gradation, and density.

- Identification of Construction Issues: Core cutting identifies construction-related issues such as poor compaction, improper layer thickness, or the presence of excess air voids, which can lead to early deterioration of the pavement.

- Assessment of Pavement Longevity: By examining core samples, engineers can predict the expected lifespan of the asphalt pavement and make recommendations for repairs or adjustments in future projects.

- Guiding Maintenance Plans: Core cutting helps identify areas that require maintenance or rehabilitation, facilitating timely intervention and prolonging the life of the pavement.

2.5 Relevant IS Code for Asphalt Core Cutting

The testing of asphalt pavements through core cutting is governed by several Indian Standard (IS) codes:

- IS 3386: This code specifies the methods for sampling and testing asphalt mixtures. It includes guidelines for core extraction, testing procedures, and result interpretation.

- IS 15642: Provides specifications for hot-mix asphalt (HMA), covering the mix design, quality control, and testing processes used in the production and construction of asphalt pavements.

- IS 1203: This standard outlines the testing methods for bitumen, which is crucial in determining the binder content in the asphalt mix.

- Testing of Core Cutting in Concrete

3.1 Description of Core Cutting in Concrete

Core cutting in concrete is the process of extracting cylindrical samples from hardened concrete structures. The core samples obtained from these structures provide essential data regarding the compressive strength, quality, and integrity of the concrete. This testing method is commonly used in structures such as bridges, buildings, and pavements, particularly when assessing existing structures or verifying compliance with design specifications.

Core cutting allows engineers to evaluate how the concrete has performed in situ, enabling them to make decisions about maintenance, rehabilitation, or even demolition if the structure does not meet the necessary standards.

3.2 Core Cutting Procedure for Concrete

The procedure for core cutting in concrete is as follows:

- Selection of Locations: Core samples should be taken from critical locations within the structure, such as areas exposed to heavy loads or aggressive environmental conditions. Multiple samples may be needed to ensure the core results are representative of the overall condition of the structure.

- Drilling: A diamond-tipped core drill is used to cut cylindrical samples from the concrete. The size of the core typically ranges from 100mm to 150mm in diameter, depending on the project requirements. Cores are cut with water to avoid excessive heat, which could alter the properties of the concrete.

- Core Extraction and Handling: The extracted cores are carefully labeled with relevant details and transported under controlled conditions. Proper handling is essential to prevent cracking or dehydration, which could skew the test results.

3.3 Core Cutting Tests and Parameters in Concrete

Key parameters tested for concrete cores include:

- Compressive Strength: Compressive strength is the most critical parameter for concrete. Cores are subjected to compressive loading in a testing machine to determine their strength. This is compared to the specified design strength to ensure that the concrete meets the structural requirements.

- Density and Air Voids: The density of the concrete is determined, and the volume of air voids is calculated. Air voids, if excessive, could lead to water penetration, freeze-thaw damage, and reduced durability.

- Cracking and Durability: Core samples are examined for signs of cracking, shrinkage, or early deterioration. These signs are often indicators of poor curing or inadequate mix design.

- Chloride Content: For concrete exposed to aggressive environments, such as marine exposure, chloride testing is performed to determine the potential for reinforcement corrosion.

3.4 Importance of Core Cutting in Concrete Testing

Core cutting is indispensable in assessing the quality and longevity of concrete structures. Some of its significant benefits include:

- Accurate Evaluation of Concrete Strength: Core cutting allows for an accurate assessment of compressive strength, ensuring that the concrete can withstand the required structural loads.

- Compliance Verification: It helps verify whether the concrete mix used on-site complies with the project’s design specifications and quality standards.

- Detection of Structural Deficiencies: Core cutting can identify issues such as cracks, inadequate curing, and poor mix design, which could compromise the concrete’s integrity and lifespan.

- Guidance for Maintenance: By understanding the current condition of the concrete, engineers can recommend specific maintenance or repair strategies to prolong the service life of the structure.

3.5 Relevant IS Code for Concrete Core Cutting

The following Indian Standards (IS) codes are essential for conducting core cutting tests in concrete:

- IS 516: “Methods of Tests for Strength of Concrete” outlines the procedures for testing the compressive strength of concrete cores and provides guidelines for evaluating the quality of concrete.

- IS 1199: “Sampling and Acceptance Criteria for Concrete” specifies the sampling and acceptance criteria for concrete cores, including the required number of samples and acceptable tolerances.

- IS 10262: This standard provides guidance for the mix design of concrete, which helps determine the suitability of the mix used in the concrete structure.

- Why Core Cutting Tests Are Conducted

4.1 Verification of Material Properties

Core cutting tests provide a reliable way to verify that the material properties, such as strength, density, and durability, meet the design specifications. For both asphalt and concrete, this ensures that the materials used are capable of performing as expected under real-world conditions.

4.2 Quality Control and Assurance

Core cutting is an important tool for quality control during construction. By extracting cores from various locations, engineers can assess whether the construction methods are being followed correctly and whether the materials are of the required standard. Core cutting helps identify areas of poor construction, such as insufficient compaction in asphalt or improper curing in concrete.

4.3 Structural Integrity Assessment

Core cutting tests are crucial for assessing the structural integrity of pavements and concrete structures. For example, by examining cores from an asphalt pavement, engineers can detect issues like cracking or rutting, which might be a result of poor compaction or inadequate binder content. Similarly, in concrete, core cutting can identify issues like voids or cracks, which can compromise the safety and stability of the structure.

- Conclusion

Core cutting is a fundamental testing method that plays a pivotal role in ensuring the quality, integrity, and durability of both asphalt pavements and concrete structures. It provides a direct means of assessing the real-world performance of materials used in construction, offering detailed insights that go beyond theoretical or design predictions. By extracting cylindrical core samples from in-situ materials, engineers can gain accurate information regarding the strength, compaction, homogeneity, and overall condition of the materials used in the pavement or structure.

The value of core cutting tests cannot be overstated, as they contribute to the overall safety, longevity, and efficiency of infrastructure projects. Through the results obtained from these tests, engineers are able to identify potential issues early in the construction process, such as poor compaction in asphalt or inadequate curing in concrete. This early identification can prevent costly repairs or premature failures in the future, ultimately leading to more reliable and durable infrastructures. In particular, core cutting helps in ensuring that the pavement or concrete structure is constructed according to the specifications and will continue to perform as expected throughout its lifespan.

Moreover, core cutting tests support the decision-making process related to maintenance and rehabilitation. By analyzing core samples, engineers can determine whether certain areas of a structure require repair or whether the entire surface or structure needs to be resurfaced or replaced. This is especially crucial for infrastructure exposed to harsh environmental conditions or heavy traffic loads, as timely interventions can significantly extend the life of the pavement or concrete structure and improve its overall performance.

In the context of regulatory compliance, core cutting tests provide assurance that construction projects are adhering to established standards and guidelines. Indian Standard codes, such as IS 3386 for asphalt and IS 516 for concrete, outline the accepted procedures for core extraction and testing, ensuring consistency and accuracy in the results. By following these standards, engineers can guarantee that the tests are performed correctly and that the results are meaningful, thereby reinforcing confidence in the constructed infrastructure’s ability to withstand the stresses and demands placed upon it.

Core cutting tests also help engineers and construction teams build a feedback loop, allowing them to evaluate and improve the quality of materials and construction techniques. For example, if issues are identified in the core samples, engineers can revisit the mix designs, construction methods, or material sourcing processes to optimize future projects. This continuous feedback ultimately leads to improved practices and enhanced performance in subsequent infrastructure projects, benefiting the industry as a whole.

Finally, core cutting is an essential practice in the ongoing maintenance and rehabilitation of roads, buildings, bridges, and other concrete or asphalt structures. It serves as a valuable tool not just for initial construction, but throughout the service life of the infrastructure. As structures age, core cutting provides critical information about their condition and helps plan for necessary repairs or upgrades, ensuring that public safety and operational efficiency are never compromised.

In conclusion, core cutting testing stands as a cornerstone of modern civil engineering, ensuring the structural integrity and long-term durability of asphalt pavements and concrete structures. By providing vital information that informs design, construction, and maintenance decisions, core cutting helps engineers make informed, data-driven choices that contribute to the development of safe, sustainable, and reliable infrastructure. The adherence to standards like IS 3386, IS 516, and other relevant codes ensures that the testing process is robust and the results are dependable, enabling the industry to build infrastructure that stands the test of time.

References

- IS 3386: Method of Sampling and Testing of Asphalt.

- IS 516: Methods of Tests for Strength of Concrete.

- IS 1199: Sampling and Acceptance Criteria for Concrete.