NSV survey (Network Survey Vehicle survey) is an automated road assessment technology used across India to evaluate highway and airport pavement conditions. This comprehensive guide explains how NSV testing works, why it’s required under MoRTH guidelines, and how transportation agencies use this data for infrastructure planning and maintenance decisions.

Network Survey Vehicle testing, commonly called NSV test, uses specialized instrumented vehicles to collect road inventory and pavement condition data for highways, urban roads, village roads, and airport pavements. The vehicle drives along roadways while continuously recording lane-wise, geo-tagged images, position logs, and surface measurements without stopping or disrupting traffic. This continuous lane capture makes it efficient for long roadways and enables repeatable condition monitoring.

In India, NSV surveys are commonly carried out on 2-lane, 4-lane, 6-lane, and 8-lane highways, expressways, urban roads, village or rural roads, and airport pavements. These surveys support activities such as planning studies, construction stage monitoring, maintenance planning, and long-term pavement asset management. Use of Network Survey Vehicle surveys has increased significantly after guidance issued by the Ministry of Road Transport and Highways (MoRTH) in November 2019, which encourages objective, repeatable, and technology-based assessment for large road networks instead of subjective visual inspection.

This content is prepared by NKMPV Research and Development LLP, an Indian infrastructure testing and survey organization working in the road and pavement domain since 2012. NKMPV undertakes Network Survey Vehicle surveys for highways, village roads, and airport pavements using calibrated camera-based 2D NSV systems. The organization operates as a NABL-accredited laboratory in accordance with ISO/IEC 17025:2017 and carries out NSV surveys as part of pavement condition assessment, road inventory documentation, and infrastructure performance evaluation across different project types throughout India.

Table of Contents

Navigate to any section to learn about NSV surveys, their applications in Indian infrastructure projects, and how Network Survey Vehicle technology supports pavement assessment and maintenance planning.

What is NSV Survey

NSV survey, short for Network Survey Vehicle survey, is a mobile survey method used for systematic collection of road inventory and pavement condition data across road and airport pavement networks. The survey is carried out using a specially equipped vehicle that moves along the pavement corridor while sensors continuously capture GPS-tagged data for each lane or pavement section. This method allows large lengths of road to be surveyed in a consistent manner without disrupting traffic movement.

Unlike manual inspection, which depends on visual judgment and often varies between observers, NSV survey in India follows a standardized process. The same type of data is collected using the same method across the entire corridor, making results repeatable and comparable over time. This feature makes it suitable for long highways, urban road networks, village roads, airport pavements, and more where uniform assessment is required.

Network Survey Vehicle testing primarily focuses on two data groups: road inventory data and pavement condition data. Together, these datasets provide a complete view of physical details and surface quality of pavement infrastructure. Data is captured in digital form and linked to precise location reference, allowing integration with planning, design, maintenance, and asset management systems.

Road Inventory Data

Road inventory data shows physical and functional elements present along a road or pavement corridor. This includes pavement type, pavement width, lane configuration, shoulder details, median type, drainage features, road markings, signage, crash barriers, access points, intersections, and roadside assets. Inventory elements are recorded with location reference and supported by image-based or panoramic visual records.

Road inventory data forms a base layer for infrastructure records. It supports planning studies, design verification, safety assessment, and long-term asset records. Because inventory data is geo-referenced, it can be updated, compared, and reused across different project stages without repeating field surveys.

Pavement Condition Data

Pavement condition data describes surface quality of pavement. Data includes surface roughness expressed as International Roughness Index (IRI), rut depth, and visible surface distresses such as cracking, potholes, bleeding, raveling, edge failure, and surface deformation. Data is collected in a lane-wise manner, which allows identification of localized issues and comparison between lanes.

Pavement condition data helps with maintenance planning, repair priority, and performance monitoring. When NSV tests are repeated at certain intervals, changes in pavement condition can be tracked precisely, helping professionals analyze degradation trends and the results of maintenance works.

Applicability of NSV test

NSV test is applicable to a wide range of road categories and pavement types. In India, Network Survey Vehicle survey is used on 2-lane, 4-lane, 6-lane, and 8-lane highways, expressways, urban roads, village or rural roads, and airport pavements such as runways, taxiways, and aprons. Applicability depends on project requirements rather than road category alone.

Overall, NSV survey India provides a structured, objective, and repeatable method for understanding condition and details of pavement infrastructure, setting a foundation for data-driven decision-making in road and airport projects.

Purpose of NSV test in Road and Airport Projects

The purpose of an NSV test is to provide objective, measurable, and repeatable information about road and airport pavement infrastructure. Unlike manual or visual inspection, it follows a defined data collection process, which allows consistent assessment across large and diverse networks.

Existing Road Condition Assessment

One primary purpose of this survey is to establish the baseline condition of pavement before construction, repairs, or major maintenance work. Baseline data captures the existing surface condition and road inventory, which later acts as a reference point for design validation, scope definition, cost estimation, and selection of required treatment measures.

Because the data is geo-referenced and lane-wise, future surveys can be directly compared with baseline results to measure improvement or deterioration in an objective manner.

Post-Construction Verification

Network Survey Vehicle test is commonly used for post-construction verification to assess quality and uniformity of completed works. Lane-wise pavement condition data helps identify early surface defects, construction-related issues, or uneven performance along the corridor.

Early identification of such issues supports timely corrective action and reduces long-term maintenance risk.

Maintenance Planning

Large road networks require a systematic approach for maintenance planning. NSV survey provides comparable condition data across the entire network, making it easier to identify critical sections that need immediate attention.

Condition-based selection allows maintenance resources to be allocated based on actual pavement performance rather than visual judgment alone. This data-driven approach improves efficiency and ensures funds are directed to areas with the greatest need.

Performance Monitoring Over Time

Repeated NSV tests support performance monitoring by tracking changes in pavement condition at defined periods. This helps agencies understand degradation trends, inspect maintenance efficiency, and validate design assumptions.

Performance monitoring plays an important role in long-term pavement management and budgeting. By comparing survey results from different time periods, agencies can calculate deterioration rates, predict future maintenance needs, and evaluate whether previous rehabilitation work achieved expected results.

NSV Survey for Airport Pavements

For airport pavements, NSV survey supports monitoring of runways, taxiways, and aprons where surface condition, smoothness, and markings directly affect operational safety. frequent tests help airport operators maintain surface performance and plan timely maintenance interventions without disrupting flight operations.

Airport pavement assessment requires particular attention to surface regularity, foreign object debris, marking visibility, and joint condition. Network Survey Vehicle technology captures these parameters systematically across the entire airside pavement network.

Recording Road and Pavement Assets

NSV survey also supports asset documentation through structured road inventory data. Geo-referenced inventory records integrate with GIS and asset management systems, supporting long-term planning, lifecycle management, and infrastructure reporting.

Overall, the purpose of Network Survey Vehicle survey is to support data-driven planning, construction oversight, maintenance decision making, and asset management for road and airport pavement infrastructure.

Why NSV Surveys are Required in India

NSV surveys are required in India to support objective, consistent, and data-driven management of road and airport pavement infrastructure. The size and diversity of India’s road network make manual inspection unreliable for uniform assessment and long-term planning.

India has a vast network of highways, urban roads, village roads, and airport pavements spanning millions of kilometers. Manual surveys across such varied infrastructure often lead to inconsistent results because different inspection teams may use different criteria or judgment standards. this enables uniform data collection across different road categories using the same method and criteria.

Visual inspection depends on individual judgment and experience, which creates variability in results. Two inspectors examining the same pavement section might provide different condition ratings based on their interpretation. NSV survey reduces this subjectivity by using standardized data capture and processing. Geo-referenced and repeatable data allows reliable comparison of pavement condition across time and locations.

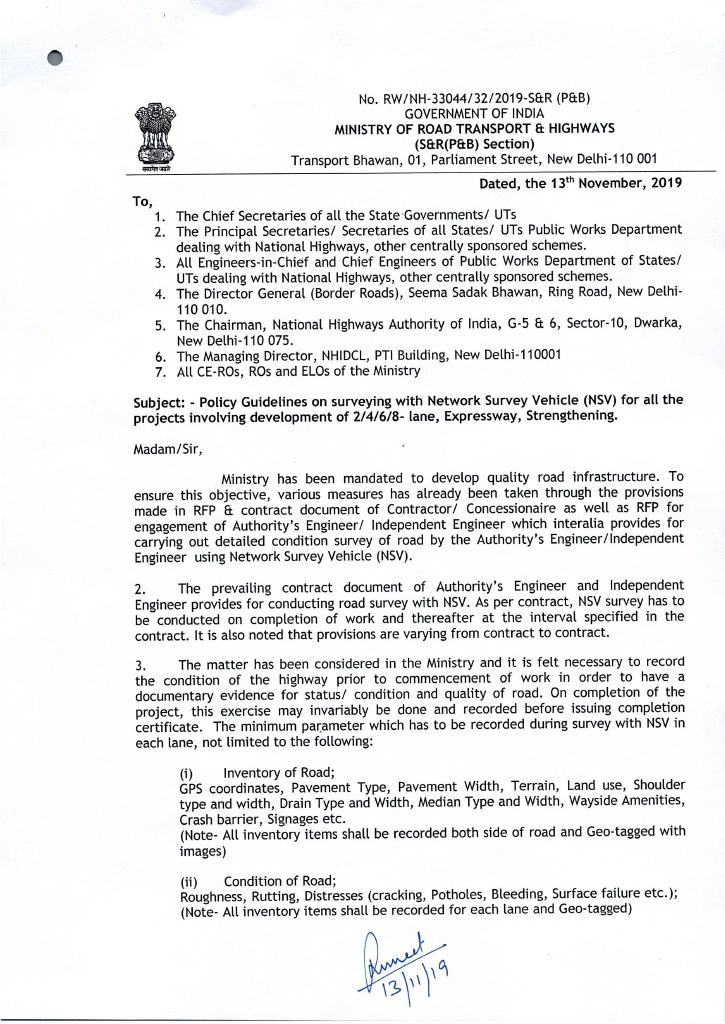

Ministry of Road Transport and Highways issued guidance in November 2019 promoting use of Network Survey Vehicle surveys for highway projects. It’s recommended before construction, after completion, and at regular intervals during operation. The policy intent is to encourage measurable and technology-based assessment instead of subjective inspection.

NSV survey data supports planning, budgeting, and maintenance prioritization at network level. Condition-based information helps identify critical sections, plan timely interventions, and optimize use of available funds. Lane-wise data further supports performance evaluation and deterioration analysis across thousands of kilometers of roadways.

Airport pavements require consistent surface condition monitoring to ensure safety and operational reliability. It support systematic assessment of runways, taxiways, and aprons, helping airport operators plan maintenance while maintaining operational schedules and meeting regulatory requirements from aviation authorities.

Increasing complexity of infrastructure projects, combined with accountability requirements for public spending, makes objective data collection essential. this test provide verifiable records that support transparent decision-making and justify infrastructure investments to stakeholders and funding agencies.

Overall, NSV surveys are required in India to enable transparent, repeatable, and data-backed decisions across planning, construction, maintenance, and operation stages of road and airport infrastructure.

How Modern NSV Surveys Are Conducted

Modern NSV surveys are conducted using planned field execution, synchronized data capture, and structured processing workflows. The survey process is designed to collect consistent and repeatable pavement condition and road inventory data across different road categories and pavement types.

NSV survey begins with planning of the survey corridor, coverage limits, lane configuration, and data requirements. Road category, traffic conditions, pavement type, and project objectives are reviewed before field work. Planning ensures survey vehicle movement, lane-wise coverage, and data quality remain consistent across the entire corridor.

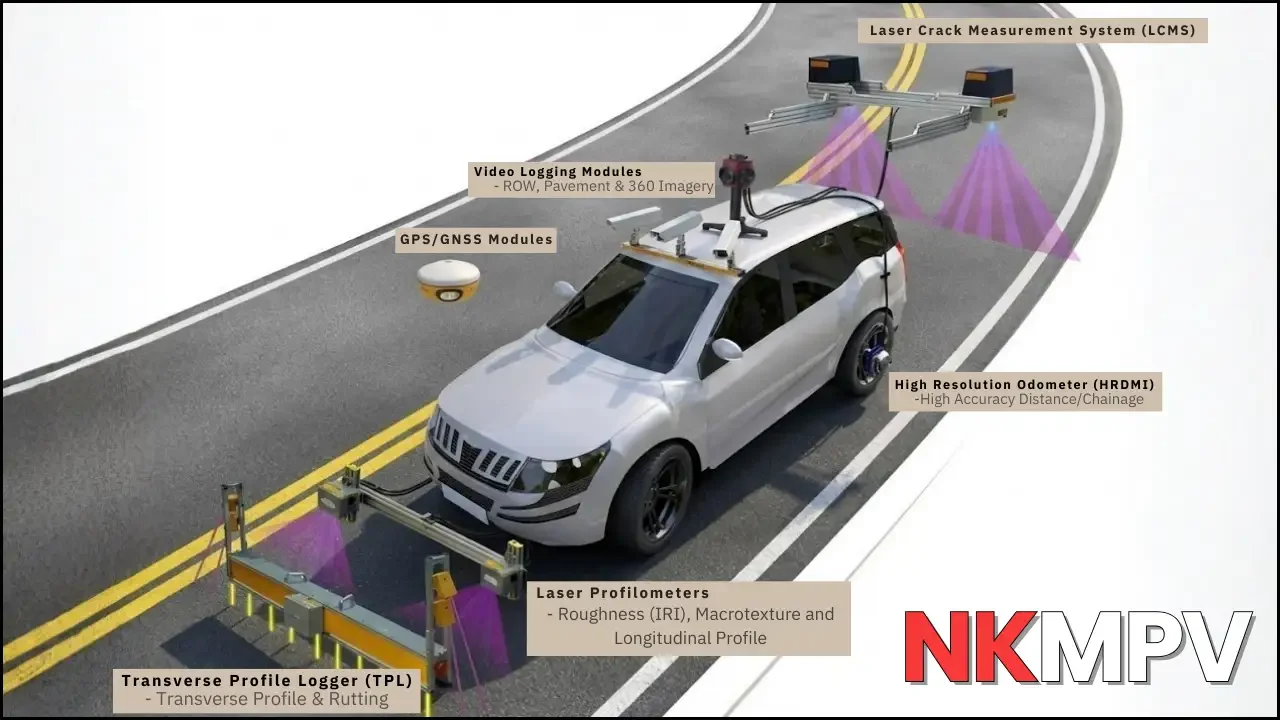

The Network Survey Vehicle is equipped with pavement cameras, forward or panoramic cameras, and positioning systems such as GNSS (Global Navigation Satellite System), IMU (Inertial Measurement Unit), and DMI (Distance Measuring Instrument). All sensors operate in a synchronized manner through an onboard data acquisition unit. Camera-based systems capture pavement surface condition and visual inventory, while positioning systems provide accurate location reference.

During field execution, the NSV vehicle travels along the pavement corridor at controlled speed under live traffic conditions. Sensors continuously capture pavement images, inventory features, and location data without need for lane closure or traffic diversion. Lane-wise data capture allows uniform assessment across the entire width of pavement.

Typical survey speeds range from 40 to 80 kilometers per hour depending on traffic conditions and road type. This speed allows NSV systems to cover 200 to 400 kilometers of roadway per day, making the technology highly efficient for large network assessments compared to manual inspection methods that might cover only 20 to 30 kilometers daily.

Collected raw data is transferred for processing using specialized software. Processing includes sensor synchronization, location validation, image review, and extraction of inventory and pavement condition parameters. Quality checks are performed to ensure completeness, consistency, and reliability of final datasets.

Processed NSV data is structured into usable formats such as maps, drawings, tables, and reports. Outputs are prepared to support planning studies, maintenance analysis, performance monitoring, and asset management activities.

Overall, the modern NSV survey process combines field execution discipline, sensor coordination, and data quality control to deliver reliable information for road and airport pavement management.

What Data is Captured During NSV Survey

NSV survey captures geo-referenced, lane-wise data describing physical characteristics and surface condition of road and airport pavements. Data is collected in consistent format to support comparison across locations, lanes, and survey cycles. Captured data broadly falls into road inventory data and pavement condition data, with additional parameters for airport pavements.

Inventory Parameters

Road inventory parameters represent physical and functional elements present along the pavement corridor. This data documents how the road or pavement is built and what assets exist within the right-of-way. Typical inventory parameters include pavement type and width, lane configuration, shoulder details, median type, drainage features, road markings, signage, crash barriers, access points, intersections, and roadside assets.

Inventory parameters are recorded with location reference and supported by visual records captured by survey cameras. Geo-referenced inventory supports mapping, documentation, safety assessment, and long-term asset records. The inventory dataset also serves as a base layer for planning studies, design checks, and integration with GIS-based management systems.

Condition Parameters

Pavement condition parameters describe surface performance of the pavement. Data includes surface roughness expressed as International Roughness Index (IRI), rut depth, and visible surface distresses. Common distress types recorded during NSV survey include longitudinal cracking, transverse cracking, alligator cracking, potholes, bleeding, raveling, edge failure, and surface deformation.

Condition data is captured lane-wise, allowing identification of localized issues and comparison between lanes. Lane-wise condition assessment supports maintenance prioritization, performance evaluation, and monitoring of deterioration trends over time. Repeat NSV surveys enable objective tracking of pavement condition changes.

International Roughness Index values typically range from less than 2 meters per kilometer for very smooth new pavements to over 8 meters per kilometer for severely deteriorated pavements. IRI measurement provides quantitative assessment of ride quality that directly affects user comfort and vehicle operating costs.

Airport Pavement Parameters

For airport pavements, NSV survey captures parameters specific to runways, taxiways, and aprons. This includes pavement geometry, surface markings, lighting elements, joints, grooves, drainage features, and visible surface defects. Surface condition parameters such as roughness, distress, and deformation are recorded to support safety and operational requirements.

Airport pavement data supports condition monitoring, maintenance planning, and documentation of airside infrastructure assets. Visual records assist in verification and review of pavement features critical to aircraft movement and airport safety compliance.

Data Consistency and Referencing

All data captured during NSV survey is linked to spatial reference using positioning systems. Geo-referenced datasets allow integration with planning tools, asset management platforms, and reporting systems. Consistent data structure ensures usability across different project stages and survey cycles.

Location accuracy typically ranges from sub-meter to few meters depending on positioning system configuration and environmental conditions. This accuracy level is sufficient for pavement management applications where condition data needs to be associated with specific road sections or chainage references.

Overall, NSV survey captures a comprehensive dataset that supports planning, maintenance, performance monitoring, and asset management for road and airport pavement infrastructure.

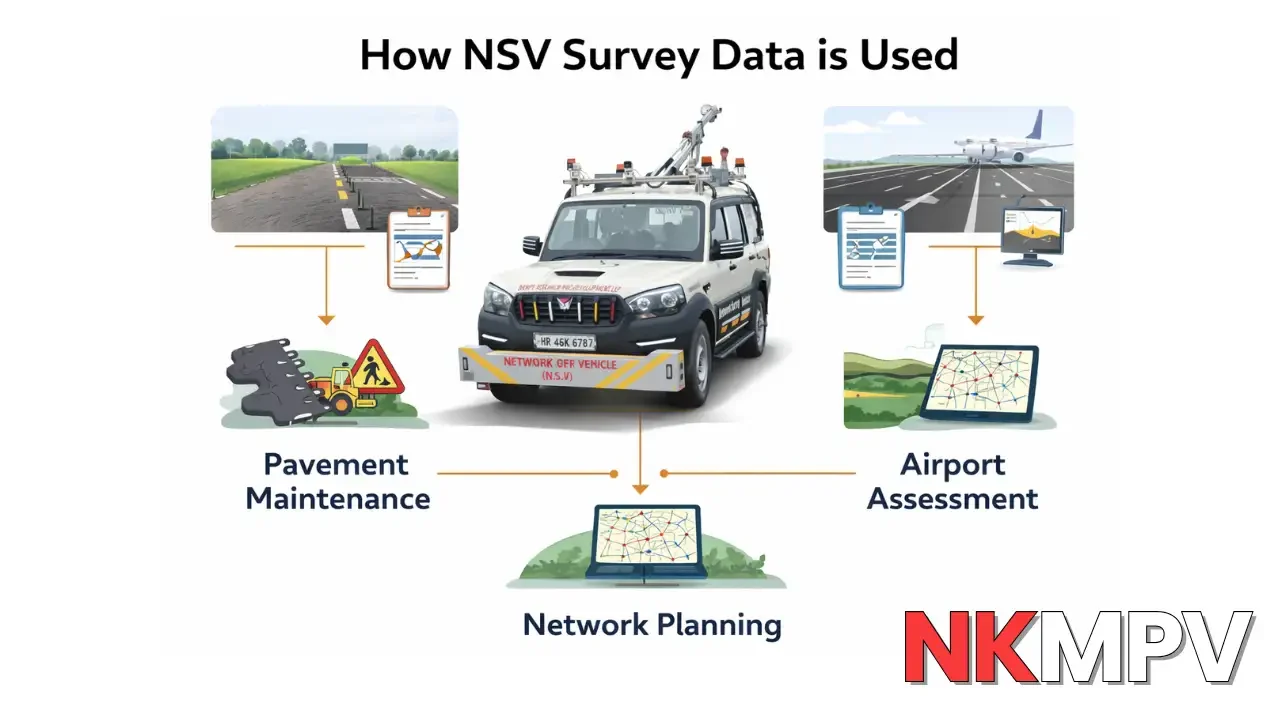

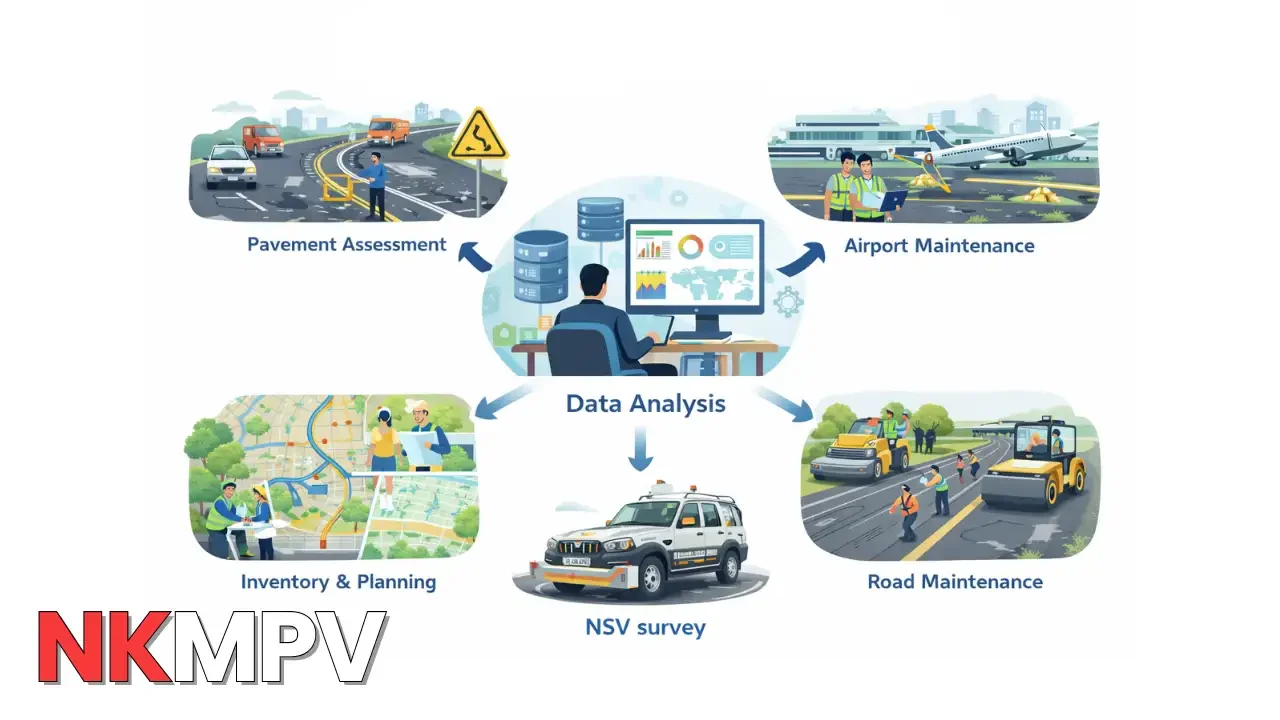

How NSV Survey Data is Used

NSV survey data is used to support planning, decision-making, and performance management across road and airport pavement infrastructure. Because data is geo-referenced, lane-wise, and repeatable, it can be applied consistently at different stages of the project lifecycle, from planning to long-term asset management.

Project Planning and DPR Preparation

NSV survey data provides reliable inputs for Detailed Project Reports (DPRs) and feasibility studies. Existing pavement condition and inventory data helps define project scope, select appropriate treatment strategies, and prepare cost estimates based on actual condition rather than assumptions. Inventory data supports alignment verification, asset identification, and design validation during the planning stage.

When preparing a DPR for highway rehabilitation, engineers use NSV survey data to identify which sections require full-depth reconstruction versus surface treatment. This precision in scope definition can reduce project costs by 15 to 25 percent compared to assumptions based on age or visual inspection alone.

Maintenance Planning and Prioritization

One primary use of NSV survey data is maintenance planning. Lane-wise pavement condition data helps identify sections with higher deterioration, safety concerns, or performance issues. Authorities can prioritize maintenance activities based on condition severity and extent, improving efficiency of resource allocation. Data-driven prioritization reduces reliance on age-based or visual-only assessment.

Highway agencies managing thousands of kilometers can use NSV data to create maintenance priority lists that ensure the worst sections receive attention first while optimizing budget utilization across the entire network.

Performance Monitoring Over Time

Repeated NSV surveys enable performance monitoring by comparing condition data across survey cycles. Changes in roughness, distress extent, or surface condition indicate deterioration trends or impact of maintenance works. Performance monitoring supports evaluation of design assumptions, construction quality, and maintenance effectiveness over time.

For example, if a rehabilitated section shows IRI increase from 2.5 to 4.5 within two years, this rapid deterioration indicates potential design or construction issues requiring investigation. Without objective NSV data, such problems might go undetected until major failures occur.

Construction Quality Assessment

NSV survey data is used to assess post-construction performance. Comparison between baseline and post-construction condition helps verify uniformity of work and identify early defects. Early identification supports corrective action before defects propagate into larger maintenance issues.

Contractors benefit from NSV test as objective documentation of delivered quality, reducing disputes about construction performance and providing clear evidence of compliance with contract specifications.

Asset Management and Documentation

NSV survey data supports asset management systems by providing structured and geo-referenced inventory records. Integration with GIS and pavement management platforms allows tracking of asset condition, maintenance history, and lifecycle planning. Accurate asset records improve long-term budgeting and infrastructure reporting.

Modern asset management systems use NSV data to predict future maintenance needs, estimate lifecycle costs, and optimize timing of interventions to maximize pavement life while minimizing overall costs.

Application for Airport Pavements

For airport pavements, NSV survey data supports monitoring of runways, taxiways, and aprons where surface condition affects safety and operational reliability. Data is used to plan maintenance interventions, verify surface quality, and maintain documentation of airside assets required by aviation regulatory authorities.

Airport operators use NSV data to schedule maintenance during low-traffic periods, minimizing disruption to flight operations while ensuring pavements remain within acceptable condition limits defined by aviation safety standards.

Overall, NSV survey data transforms field observations into usable, objective information that supports planning, maintenance, performance evaluation, and long-term management of road and airport pavement infrastructure.

Types of NSV Survey Systems

NSV survey systems are classified based on survey objectives, required outputs, and project scope, rather than hierarchy of technology. Different NSV systems are used to capture different types of data, depending on what information is needed for planning, monitoring, or asset management.

2D Network Survey Vehicle Survey

2D NSV survey is a camera-based survey method focused on pavement surface condition and road inventory. The system uses high-resolution pavement cameras, forward or panoramic cameras, and positioning sensors to capture geo-referenced data in two dimensions, covering pavement length and width.

2D NSV survey captures visual surface distresses, pavement markings, inventory features, and surface condition indicators. This approach is widely used for highway, urban road, village road, and airport pavement projects where deliverables emphasize pavement condition assessment, inventory documentation, and routine monitoring rather than three-dimensional geometric modeling.

Camera resolution typically ranges from 2 to 8 megapixels per camera, allowing detection of pavement distresses as small as 3 to 5 millimeters in width. This resolution is sufficient for identifying cracks, potholes, and other surface defects relevant to pavement management decisions.

2D NSV survey is suitable for baseline condition assessment, post-construction verification, maintenance planning, and performance monitoring across large networks. The technology provides cost-effective solution for projects where surface-level assessment meets project requirements.

NSV System Selection Based on Project Requirements

Selection of NSV survey system depends on project requirements and expected deliverables. Factors influencing selection include road category, pavement type, survey objectives, accuracy needs, and intended use of data. Where surface condition and inventory data are primary requirements, 2D NSV survey provides an effective and accepted solution.

Advanced NSV systems may incorporate additional sensors such as laser profilers for continuous roughness measurement, ground-penetrating radar for subsurface assessment, or LiDAR for three-dimensional geometry capture. These enhanced systems suit projects requiring detailed geometric modeling, structural evaluation, or precise cross-section documentation.

Different NSV approaches are used in industry practice to meet different project needs. Selection is driven by outcome requirements rather than technology preference. Clear definition of scope and deliverables ensures NSV survey outputs remain aligned with planning, maintenance, and asset management objectives.

Project teams should evaluate NSV system capabilities against specific requirements such as required accuracy levels, distress detection resolution, coverage area, timeline constraints, and budget considerations. Matching system capabilities to actual needs ensures efficient use of resources and appropriate data quality for intended applications.

Overall, NSV survey systems are selected to match what data is needed, ensuring efficiency, relevance, and usability of survey results.

NSV Survey Deliverables

NSV survey deliverables are prepared to provide clear, usable, and structured outputs that support planning, maintenance, performance evaluation, and asset management for road and airport pavement infrastructure. Deliverables are derived from processed NSV data and organized in formats suitable for engineering analysis and reporting.

Pavement Condition Outputs

Pavement condition deliverables include lane-wise condition information describing surface performance of pavement. Typical outputs include International Roughness Index (IRI) values, rut depth measurements, and mapped surface distresses such as cracking, potholes, bleeding, raveling, edge failure, and surface deformation. Condition outputs allow comparison of pavement performance across lanes, sections, and survey cycles.

Condition datasets support maintenance planning, rehabilitation prioritization, and performance monitoring. Repeated NSV surveys enable tracking of deterioration trends and assessment of maintenance effectiveness.

Deliverables typically include tabular data showing condition values at regular intervals (such as every 50 or 100 meters), graphical presentations showing condition variation along the corridor, and summary statistics for different pavement sections or project limits.

Road and Pavement Inventory Outputs

Road and pavement inventory deliverables document physical features present along the pavement corridor. Inventory outputs include mapped information on pavement geometry, shoulders, medians, drainage elements, road markings, signage, crash barriers, access points, and roadside assets. Inventory data is provided with spatial reference to support mapping and documentation.

Inventory outputs form a base layer for planning studies, design validation, safety assessment, and asset documentation. The geo-referenced nature of inventory data allows updates and comparisons without repeating entire field surveys.

Visual and Image-Based Outputs

NSV survey also provides geo-tagged pavement images and visual records captured by survey cameras. These outputs support visual verification of pavement condition and inventory features. Image-based deliverables assist in review, auditing, and communication of survey findings.

Users can virtually drive the surveyed corridor through image sequences, inspecting specific locations in detail without field visits. This capability is particularly valuable for quality reviews, dispute resolution, and verification of automated distress detection results.

Data Formats and Reporting

NSV survey deliverables are provided in commonly used formats such as tables, spreadsheets, CAD drawings, GIS shapefiles, and technical reports. Data can be integrated with GIS platforms, pavement management systems, and asset management tools used by infrastructure agencies.

Standard reporting formats include executive summary reports, detailed technical reports with methodology and findings, condition rating reports with recommendations, and digital databases compatible with pavement management software systems.

Integration capabilities allow NSV data to feed directly into decision-support tools, budget planning models, and long-term asset management platforms used by highway authorities and airport operators.

Overall, NSV survey deliverables convert raw field data into structured outputs that support informed and data-driven decision-making for road and airport pavement projects.

Why Execution Quality Matters

Quality of NSV survey results depends not only on equipment used but also on planning, field execution, and data processing practices. Even well-configured survey systems can produce unreliable outputs if execution quality is not maintained throughout the survey lifecycle.

Importance of Field Execution

Field execution plays a critical role in NSV survey quality. Proper sensor mounting, calibration, and synchronization are required before data collection begins. Inconsistent vehicle speed, poor lane discipline, or unstable sensor alignment can affect lane-wise accuracy and data continuity. Careful execution ensures uniform data capture across the entire corridor and minimizes gaps or inconsistencies.

Role of Calibration and Quality Checks

Calibration of cameras and positioning systems is essential to maintain accuracy of spatial reference. Regular calibration checks help ensure data captured during survey aligns correctly with actual pavement location. Quality checks during field work allow early identification of issues, reducing risk of data loss or re-survey.

Camera calibration involves verifying image resolution, focus, exposure settings, and field of view to ensure consistent image quality across the entire survey. Positioning system calibration ensures GPS coordinates and distance measurements align with actual ground locations within acceptable tolerance limits.

Data Processing and Validation

Post-processing of NSV data is equally important. Raw data must be validated, synchronized, and reviewed before extraction of pavement condition and inventory parameters. Errors in processing can distort condition values or inventory mapping, reducing usefulness of outputs. Structured validation procedures help ensure consistency and reliability of final datasets.

Automated distress detection algorithms require verification through manual review by experienced pavement engineers. While automation improves efficiency, human expertise remains essential for interpreting complex distress patterns and validating automated results.

Impact on Decision-Making

High execution quality ensures NSV survey outputs remain dependable for planning, maintenance, and performance evaluation. Poor execution can lead to incorrect prioritization, inefficient resource allocation, and unreliable performance tracking. Consistent execution quality supports confidence in data-driven decisions.

Organizations using NSV survey data for multi-million dollar infrastructure investments require assurance that data quality meets professional standards. Execution quality directly affects the reliability of decisions based on that data.

Quality Assurance Standards

Reputable NSV survey providers follow documented quality assurance procedures and maintain accreditation from recognized bodies such as NABL (National Accreditation Board for Testing and Calibration Laboratories). ISO/IEC 17025:2017 accreditation demonstrates commitment to quality management, technical competence, and reliable results.

Overall, execution quality determines whether NSV survey data can be trusted for long-term infrastructure management and operational planning.

Frequently Asked Questions

What is the difference between NSV survey and manual pavement inspection?

NSV survey uses instrumented vehicles with cameras and sensors to automatically capture pavement condition data while traveling at normal traffic speeds. Manual inspection relies on visual observation by engineers walking or driving slowly along the pavement. NSV test provides objective, repeatable, geo-referenced data that can be compared across time and locations. Manual inspection results vary based on inspector judgment and experience. Network Survey Vehicle survey can cover 200 to 400 kilometers per day compared to 20 to 30 kilometers for manual methods, making them more efficient for large networks.

How much does an NSV survey cost in India?

NSV survey costs vary based on road length, lane configuration, data requirements, and project complexity. Typical costs range from 15,000 to 40,000 rupees per lane-kilometer depending on specifications. Factors affecting cost include required data accuracy, deliverable formats, processing complexity, and timeline requirements. While NSV test have higher upfront costs than visual inspection, they provide more comprehensive data that reduces long-term costs through better maintenance planning and prioritization. Project teams should request detailed quotations that specify scope, deliverables, and quality standards.

How long does it take to complete an NSV survey?

Field data collection typically covers 200 to 400 kilometers per day depending on traffic conditions and road type. For a 100-kilometer highway corridor, field work usually takes 1 to 2 days. Data processing and report preparation typically requires 2 to 4 weeks after field completion depending on data volume and deliverable complexity. Rush projects with expedited timelines may be accommodated with additional resources. Overall project duration from mobilization to final deliverable submission typically ranges from 3 to 6 weeks for standard highway projects.

Which government agencies require NSV surveys in India?

The Ministry of Road Transport and Highways (MoRTH) issued guidelines in November 2019 recommending Network Survey Vehicle survey for National Highway projects. State highway agencies including PWD (Public Works Department), NHAI (National Highways Authority of India), NHIDCL (National Highways and Infrastructure Development Corporation Limited), and BRO (Border Roads Organisation) increasingly require Network Survey Vehicle test for highway projects. Airport Authority of India (AAI) and private airport operators use NSV testing for airside pavement management. PMGSY (Pradhan Mantri Gram Sadak Yojana) projects also utilize NSV technology for rural road assessment in several states.

Can NSV surveys be conducted during rainy season?

NSV surveys require dry pavement conditions for accurate data collection. Rain, water pooling, or wet pavement surfaces interfere with camera-based distress detection and can produce unreliable condition data. Surveys are typically scheduled during dry weather periods. If rain occurs during field work, the survey is paused and resumed when pavements dry. Project planning should consider seasonal weather patterns to avoid monsoon periods. Post-monsoon and winter months generally provide optimal conditions for NSV tests across most of India.

What is the accuracy of GPS coordinates in NSV survey data?

GPS positioning accuracy in NSV surveys typically ranges from sub-meter to 2-3 meters depending on system configuration and environmental conditions. Systems using differential GPS or RTK (Real-Time Kinematic) corrections achieve higher accuracy levels around 0.1 to 0.5 meters. Standard GNSS systems provide accuracy of 1 to 3 meters, which is sufficient for pavement management applications where condition data needs to be associated with road sections or chainage references. Location accuracy specifications should be clarified during project scope definition based on intended use of data.

How often should NSV surveys be repeated for performance monitoring?

Survey frequency depends on pavement type, traffic volume, deterioration rates, and management objectives. Newly constructed or rehabilitated highways typically require NSV surveys at project completion, after one year, and then every 2 to 3 years during warranty period. Mature highway networks benefit from NSV assessment every 3 to 5 years for condition monitoring and maintenance planning. High-traffic urban roads may require annual surveys. Airport pavements are often surveyed annually or bi-annually to ensure operational safety. Agencies should establish survey frequencies based on network size, budget availability, and decision-making cycles.

Can NSV survey detect subsurface pavement problems?

Standard camera-based 2D NSV surveys primarily detect visible surface distresses and cannot directly assess subsurface conditions. However, certain surface distresses like alligator cracking, rutting, and deformation often indicate underlying structural problems. Advanced NSV systems can incorporate ground-penetrating radar or deflection measurement equipment to assess subsurface and structural conditions. Projects requiring comprehensive structural evaluation should specify these additional capabilities during scope definition. For most maintenance planning applications, surface condition data from standard NSV surveys combined with selective structural testing provides cost-effective assessment.

What qualifications should NSV survey providers have?

Reputable NSV survey providers should have: calibrated equipment with documented maintenance records; experienced pavement engineers for data interpretation and quality review; quality management systems such as ISO/IEC 17025:2017 accreditation from NABL or equivalent bodies; demonstrated experience on similar road categories and project types; ability to deliver data in required formats compatible with client systems; transparent methodology and quality assurance procedures; adequate insurance coverage and safety protocols. Project teams should verify provider credentials, review past project experience, and clearly define deliverable specifications in contracts.

How is NSV survey data integrated with pavement management systems?

NSV survey data is typically provided in standardized formats compatible with common pavement management software platforms. Data integration involves importing geo-referenced condition and inventory data into the management system database, associating data with existing road network segmentation, and configuring visualization and analysis tools. Most modern pavement management systems support direct import of NSV data through standard file formats like CSV, shapefile, or database formats. Custom integration may be required for legacy systems. Data integration capabilities should be discussed with NSV provider and software vendor during project planning.

What happens if NSV survey data shows unexpected results?

Unexpected results should first be verified through review of raw data, survey images, and processing methodology. Visual image review allows verification of automated distress detection results and condition ratings. If unexpected results are confirmed as accurate, they may indicate actual pavement issues requiring attention. In cases where data quality issues are identified, affected sections can be re-surveyed or supplemented with field verification. Quality assurance procedures including independent data review help minimize such occurrences. Clients should work with NSV providers to understand results, verify findings through image review, and determine appropriate follow-up actions.

Are NSV surveys accepted by consultants and approval authorities?

NSV surveys are widely accepted by highway consultants, DPR preparation firms, and government approval authorities in India, particularly since MoRTH guidelines recommended their use in 2019. Many consultants now specify NSV inspections as standard practice for baseline assessment and performance monitoring in project terms of reference. Acceptance depends on survey being conducted by qualified providers using calibrated equipment and following recognized methodologies. Projects should ensure NSV validation specifications align with relevant standards and guidelines. Proper documentation of methodology, quality assurance procedures, and calibration records supports acceptance by all project stakeholders.

Getting Started With NSV Surveys

Organizations planning to use Network Survey Vehicle surveys for highway or airport projects should consider several factors to ensure successful implementation and useful results.

Defining Survey Objectives

Clear definition of survey objectives is the first step. Determine whether the survey is for baseline assessment, post-construction verification, maintenance planning, performance monitoring, or asset documentation. Different objectives may require different data parameters, accuracy levels, and deliverable formats. Well-defined objectives ensure survey outputs match intended use and support decision-making requirements.

Selecting Appropriate Survey Scope

Survey scope should specify corridor limits, lane configuration, required data parameters, accuracy standards, and deliverable formats. Consider whether inventory data, condition data, or both are required. For airport projects, specify which pavement areas (runways, taxiways, aprons) require assessment. Clear scope definition prevents misunderstandings and ensures proposals from different providers can be compared effectively.

Evaluating NSV Survey Providers

When evaluating NSV survey providers, verify equipment capabilities, calibration procedures, quality assurance systems, and relevant project experience. Ask for sample deliverables from similar projects to assess data quality and presentation formats. Check for accreditation from recognized bodies such as NABL and verify the provider’s technical team includes experienced pavement engineers capable of interpreting automated results and providing expert review.

Review provider references from past projects, particularly projects with similar road categories and technical requirements. Reliable providers should demonstrate consistent delivery of quality results within agreed timelines.

Understanding Deliverables and Timelines

Clearly understand what deliverables will be provided, in what formats, and within what timeframe. Typical deliverables include condition data tables, distress maps, inventory documentation, geo-tagged images, and technical reports. Verify that data formats are compatible with your organization’s existing systems such as GIS platforms or pavement management software.

Establish realistic timelines that account for field mobilization, weather dependencies, data processing, quality review, and report preparation. Rush projects may require premium pricing or may compromise data quality.

Quality Assurance and Acceptance Criteria

Define quality assurance requirements and acceptance criteria in project specifications. This may include requirements for calibration certificates, sample data review during fieldwork, validation procedures, and independent quality checks. Clear acceptance criteria help ensure delivered data meets requirements and reduces potential disputes.