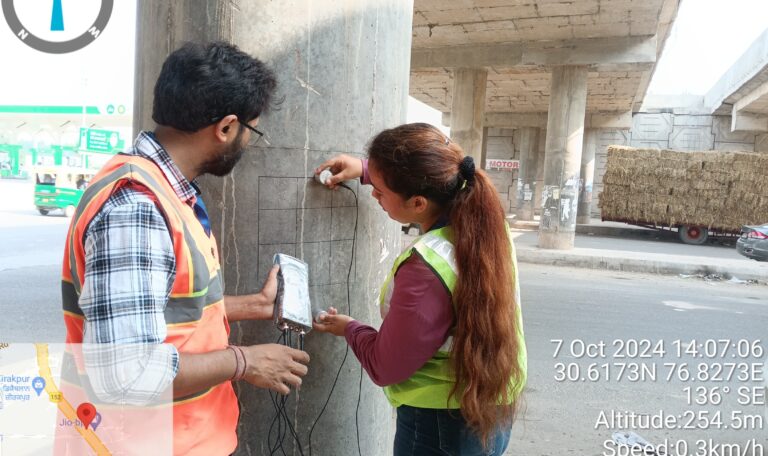

Ultrasonic Pulse Velocity (UPV) Test

Ultrasonic Pulse Velocity (UPV) Test: A Comprehensive Study

Introduction

The Ultrasonic Pulse Velocity (UPV) test is one of the most widely used non-destructive testing (NDT) methods in civil engineering. It is used to assess the quality, homogeneity, and integrity of construction materials, especially concrete. By transmitting high-frequency ultrasonic pulses through a material and measuring their travel time, this test provides crucial data on the material’s properties, including its density, elasticity, strength, and the presence of voids or cracks. It serves as a key tool in ensuring the longevity and safety of structures. This report explores the principles, benefits, applications, uses, objectives, equipment, procedures, and code references associated with the UPV test.

Principle of the Ultrasonic Pulse Velocity Test

The UPV test relies on the basic principle that sound waves travel through materials at a velocity that is influenced by the material’s properties. Ultrasonic pulses are transmitted through the material, and the time taken for these waves to travel from one transducer to another is measured. The velocity of the pulses, termed as pulse velocity, is calculated using the formula:

V=LTV = \frac{L}{T}V=TL

Where:

- VVV= Pulse velocity (m/s)

- LLL= Distance between the transducers (m)

- TTT= Transit time (s)

The pulse velocity is highly dependent on the material’s elasticity, density, and microstructure. Changes in these material properties can cause variations in the pulse velocity, providing insight into the material’s condition. For instance, a high pulse velocity typically indicates a dense, homogeneous material, while a low pulse velocity might suggest the presence of cracks, voids, or other internal defects.

Benefits of the UPV Test

The UPV test offers a wide range of benefits that make it indispensable in construction and material testing. Some of the key advantages are as follows:

- Non-Destructive Testing:The primary advantage of the UPV test is that it is non-destructive. The test does not cause any damage to the material being tested, making it ideal for assessing in-service structures, such as bridges, dams, and buildings, without affecting their integrity.

- High Sensitivity:UPV is capable of detecting even minor defects, such as micro-cracks, voids, and honeycombing, which may not be visible to the naked eye or detectable by other testing methods. This high sensitivity makes the UPV test highly effective in early defect detection.

- Efficiency and Speed:The test provides results rapidly, often within minutes, which is especially useful in large-scale construction projects or when quick assessments are necessary. This efficiency supports timely decision-making and planning.

- Cost-Effective:By reducing the reliance on destructive testing methods, the UPV test helps lower costs associated with material waste, repair, and downtime, making it a more affordable alternative for routine inspections.

- Versatility:The UPV test can be applied to a variety of materials, including concrete, rocks, ceramics, and even some metals. This versatility makes it valuable across multiple industries, from construction and infrastructure maintenance to material research and geotechnical investigations.

- Correlation with Material Strength:The UPV test is often used to estimate the compressive strength of concrete. A correlation between pulse velocity and strength has been well established, providing engineers with a reliable method to estimate the load-bearing capacity of concrete without the need for destructive testing.

- Environmentally Friendly:The non-invasive nature of the test makes it environmentally friendly. It reduces the need for material replacement and helps prevent the wasteful disposal of concrete or other building materials.

- Enhancing Safety:By identifying internal defects early, the UPV test enhances structural safety. Early detection of cracks or voids can help prevent catastrophic structural failures or accidents, ensuring the safety of both workers and the general public.

Applications of the UPV Test

The UPV test has widespread applications in various industries. Its versatility allows it to be used in many contexts, from new construction projects to the maintenance and monitoring of existing infrastructure. Some of the most common applications are outlined below:

- Quality Control in Construction:The UPV test is often employed to verify the quality and uniformity of concrete during construction. It helps identify any variations in the material’s properties, such as areas with reduced strength or the presence of voids, which may affect the structural integrity.

- Structural Health Monitoring:As infrastructure ages, it undergoes wear and tear that may lead to deterioration. The UPV test can be used for ongoing structural health monitoring, detecting changes over time and assisting in the early identification of damage, such as cracking or corrosion in reinforced concrete structures.

- Assessment of Repairs:When repairs or retrofitting work is carried out on structures, the UPV test can be used to assess the effectiveness of these measures. By comparing UPV readings before and after repairs, engineers can determine if the desired improvements have been achieved.

- Material Characterization:Researchers use the UPV test to study the properties of new construction materials. It provides insights into material homogeneity, density, and strength, which are important for the development of innovative building materials with enhanced performance characteristics.

- Geotechnical Investigations:In geotechnical engineering, the UPV test is used to assess the quality of rock formations and soil. It helps determine the uniformity and integrity of the ground materials, which is critical for the design and stability of foundations and tunnels.

- Forensic Investigations:After structural failures or accidents, the UPV test can help identify the causes of the failure. By measuring the pulse velocity of the damaged material, engineers can determine whether defects, such as cracks or voids, contributed to the collapse or failure.

- Heritage Preservation:The UPV test is also widely used in the preservation of historical buildings and monuments. It provides a non-invasive method for evaluating the structural condition of heritage structures, ensuring that repairs and restorations are carried out without causing further damage.

- Industrial Applications:The UPV test is increasingly being used to assess the integrity of industrial components, such as pipes, storage tanks, and pressure vessels. It helps ensure the reliability and safety of critical infrastructure in industries like oil and gas, power generation, and manufacturing.

Uses of the UPV Test

The primary uses of the UPV test can be categorized as follows:

- Detection of Cracks and Voids:The UPV test is highly effective in identifying internal defects, such as cracks and voids, which compromise the structural integrity of materials. Early detection of these defects is crucial for maintenance and safety.

- Evaluation of Elastic Properties:The test can be used to estimate the elastic modulus and other related properties of materials. These properties are essential for understanding how the material will perform under load and are critical for structural design.

- Homogeneity Assessment:By measuring pulse velocity across different points of a material, the UPV test can assess its uniformity. Materials with a high level of homogeneity tend to exhibit more consistent mechanical properties, which contribute to structural reliability.

- Determination of Concrete Strength:The UPV test is commonly used to estimate the compressive strength of concrete. Pulse velocity correlates with concrete strength, allowing engineers to indirectly assess the load-bearing capacity of concrete without the need for expensive and time-consuming destructive testing.

- Long-Term Monitoring:The UPV test is used for long-term monitoring of concrete structures. By performing periodic testing, engineers can track changes in the material’s properties over time, providing valuable data on the durability and performance of the structure.

Need for the UPV Test

There is an increasing need for the UPV test due to several factors related to the modern construction environment:

- Structural Integrity Verification:In an era of increasing construction activity, ensuring the structural integrity of buildings and infrastructure is crucial. The UPV test provides a reliable means of verifying the quality of materials used in construction without compromising the structure.

- Rapid Assessment:In many situations, a quick assessment of material quality is needed, especially for large-scale construction projects. The UPV test provides rapid, reliable results, enabling engineers to make timely decisions.

- Aging Infrastructure:As infrastructure ages, the need for ongoing monitoring and maintenance becomes more pressing. The UPV test allows for the periodic evaluation of aging structures, helping to identify potential risks and enabling appropriate maintenance actions.

- Repair Validation:After repairs or strengthening work, it is essential to verify that the desired outcomes have been achieved. The UPV test offers a reliable means of assessing the effectiveness of these interventions.

- Supplementary Testing:The UPV test is often used in conjunction with other testing methods, such as destructive tests, to provide a more comprehensive evaluation of material properties.

- Regulatory Compliance:Many construction codes and standards require non-destructive testing as part of the material testing and quality assurance process. The UPV test helps ensure compliance with these regulations.

Code References

The UPV test is standardized by several international codes and standards. These guidelines ensure consistency, reliability, and quality in testing practices. Some of the prominent codes include:

- ASTM C597:The American Society for Testing and Materials (ASTM) provides the Standard Test Method for Pulse Velocity Through Concrete, which outlines the procedures and requirements for conducting UPV tests on concrete.

- IS 13311 (Part 1):The Indian Standard for Non-Destructive Testing of Concrete covers the UPV method and its applications in the evaluation of concrete structures.

- BS EN 12504-4:The European Standard for Testing Concrete focuses on ultrasonic pulse velocity measurements, providing guidelines for testing and interpretation of results.

- ACI 228.2R:The American Concrete Institute offers guidelines for evaluating concrete using non-destructive methods, including the UPV test, ensuring that testing is done in accordance with industry best practices.

Objectives of the UPV Test

The Ultrasonic Pulse Velocity (UPV) test is widely used in civil engineering and material science for evaluating the quality and integrity of materials, particularly concrete. The objectives of the UPV test are multifaceted, covering a broad spectrum of purposes ranging from quality assurance during construction to long-term monitoring of infrastructure. The primary objectives of the UPV test include the following:

- Material Homogeneity:One of the key objectives of the UPV test is to assess the uniformity and consistency of materials, particularly concrete. By measuring pulse velocity at various points across a structure, engineers can determine whether the material is homogeneous or if there are any variations in its properties. Inhomogeneities in the material can be indicative of problems such as poorly mixed concrete, improper curing, or the presence of segregated aggregates, all of which can compromise the structural performance. The test helps ensure that materials are distributed evenly and that there are no unexpected variations in the material quality.

- Structural Integrity:The UPV test is used to detect internal defects that may affect the structural integrity of a material. These defects could include cracks, voids, honeycombing, delaminations, and other discontinuities within concrete or other construction materials. The ability to detect these issues non-destructively helps engineers assess the overall health of a structure without the need for invasive testing or potential damage. This objective is especially critical for aging infrastructure or in-service structures, where detecting hidden damage early can prevent catastrophic failures.

- Quality Assurance:The UPV test plays a significant role in ensuring that materials meet the necessary quality standards during construction and after repairs. Quality assurance through UPV testing involves verifying that the materials used, such as concrete, meet the required specifications for strength, durability, and performance. For example, UPV testing can help ensure that the compressive strength of concrete aligns with the design specifications without the need for destructive testing methods, which can be costly and time-consuming. Regular UPV testing during construction also allows for real-time adjustments to processes, improving overall quality control.

- Strength Estimation:While the UPV test is not a direct measure of material strength, it provides an indirect estimation of compressive strength, particularly for concrete. Pulse velocity correlates with the compressive strength of concrete, with higher velocities generally indicating stronger, more durable material. By establishing a relationship between pulse velocity and compressive strength, engineers can quickly assess the strength of concrete without performing expensive and labor-intensive core tests. This estimation can be valuable for ensuring that structures are safe and capable of bearing the anticipated loads without requiring destructive testing procedures.

- Damage Assessment and Forensic Investigation:The UPV test is also an important tool for evaluating the extent of damage caused by environmental factors, mechanical loads, or aging. This is particularly crucial for forensic investigations after structural failures, natural disasters, or accidents. The test helps identify the underlying causes of failure by detecting anomalies in the material’s properties that might have contributed to the collapse or degradation of a structure. By assessing the pulse velocity in damaged or distressed areas, engineers can estimate the level of deterioration and identify whether further repairs or reinforcement are required.

- Long-Term Monitoring and Durability Assessment:Over time, construction materials, especially concrete, undergo changes due to environmental exposure, aging, and wear. Long-term monitoring using the UPV test provides valuable information about how materials change over their lifespan. This can include the detection of early-stage deterioration, such as cracking due to shrinkage, freeze-thaw cycles, or corrosion of reinforcement. Monitoring pulse velocity over time can help assess the ongoing durability of a structure, guiding decisions on when repairs or maintenance are needed to extend the service life of the infrastructure. The ability to track changes over time provides a proactive approach to maintenance, reducing the likelihood of unexpected failures.

- Evaluating the Effectiveness of Repairs and Rehabilitation:After repair or rehabilitation work, it is essential to assess whether the intervention has effectively restored the material’s strength and integrity. The UPV test can be used to evaluate the success of these repairs by comparing pulse velocity values before and after the work. If pulse velocities increase after repairs, it suggests that the material’s integrity has been restored. Conversely, unchanged or lower velocities may indicate that the repair has not achieved the desired outcome, prompting further action. This objective is critical for verifying the quality of repair materials and ensuring that the repaired structure meets safety standards.

- Identifying Corrosion and Other Environmental Impacts:The UPV test can also be used to identify the impact of corrosion, especially in reinforced concrete. Corrosion of the steel reinforcement within concrete can lead to expansion and cracking, which ultimately weakens the material. The UPV test can help detect areas of concrete where corrosion may have occurred by measuring lower pulse velocities in affected zones. In addition, the test can be used to evaluate other environmental impacts, such as degradation caused by chemical reactions, which might lead to the formation of cracks, voids, or loss of material strength.

- Guiding Structural Design and Retrofitting:The UPV test provides valuable data that can be used to inform the design and retrofitting of structures. For example, when a new material or mix is being tested for use in a construction project, the UPV test can offer early insights into its expected behavior, strength, and durability. For retrofitting projects, the test helps engineers determine if the current material meets the strength and stability requirements for additional loads. Pulse velocity measurements can assist in determining whether the existing structure can accommodate new design elements, such as additional floors or higher load-bearing capacities.

- Cost-Effective Testing and Monitoring:The UPV test provides a cost-effective solution for evaluating material quality, particularly when compared to traditional destructive testing methods. Destructive testing often involves taking core samples, which can be expensive and result in the loss of valuable material. Additionally, the UPV test is fast, allowing for widespread testing across a structure with minimal disruption. This makes it particularly useful for large-scale projects or structures that require ongoing monitoring, as it helps reduce the cost of maintaining and upgrading infrastructure over time.

- Supplementing Other Testing Methods:While the UPV test is highly effective on its own, it is often used in conjunction with other testing methods, such as visual inspections, rebound hammer tests, and core sampling, to provide a more complete evaluation of material properties. By combining UPV results with those from other testing techniques, engineers can obtain a more comprehensive understanding of a material’s condition, leading to more accurate assessments and better-informed decision-making. This multi-method approach is particularly important when dealing with complex materials or structures that may exhibit multiple types of deterioration.

- Supporting Regulatory Compliance and Standards:Many construction codes, standards, and regulatory frameworks require non-destructive testing (NDT) as part of the material quality assessment process. The UPV test is often included as a recommended or required method for verifying that materials meet design and safety standards. For instance, standards such as ASTM C597, IS 13311, and BS EN 12504-4 incorporate pulse velocity testing into their guidelines for evaluating concrete quality. By fulfilling these regulatory requirements, engineers ensure that the materials used in construction comply with industry standards, promoting safety and reliability.

- Improving Sustainability in Construction:The UPV test also contributes to the growing emphasis on sustainability in construction. By providing a non-destructive method for assessing material quality and detecting internal defects, it helps reduce the need for material waste and replacement. Instead of demolishing or replacing compromised materials, engineers can use UPV testing to identify areas that can be repaired or reinforced, minimizing waste and reducing the environmental impact of construction projects. The ability to conduct regular, non-invasive testing also supports the long-term sustainability of infrastructure by helping to maintain and extend the life of existing structures.

- Reducing Maintenance Costs and Downtime:The UPV test helps reduce the costs and downtime associated with maintenance and repair work. By detecting defects early, engineers can plan maintenance activities more effectively, addressing issues before they escalate into more severe problems that would require extensive repairs or even the replacement of structural elements. The ability to identify material deterioration at an early stage allows for targeted, cost-efficient interventions, which ultimately lowers maintenance costs and extends the service life of infrastructure.

Conclusion

The Ultrasonic Pulse Velocity (UPV) test plays a crucial role in non-destructive testing, offering an efficient, reliable, and non-invasive method of evaluating the quality and integrity of construction materials. Its numerous benefits, wide-ranging applications, and cost-effectiveness make it a critical tool in civil engineering, construction, and infrastructure maintenance. Although the UPV test has some limitations, such as its reliance on surface preparation and couplant efficiency, advancements in technology and methodology continue to enhance its effectiveness and expand its potential uses. Moving forward, the UPV test is poised to remain an essential tool in ensuring the safety, durability, and sustainability of our built environment.